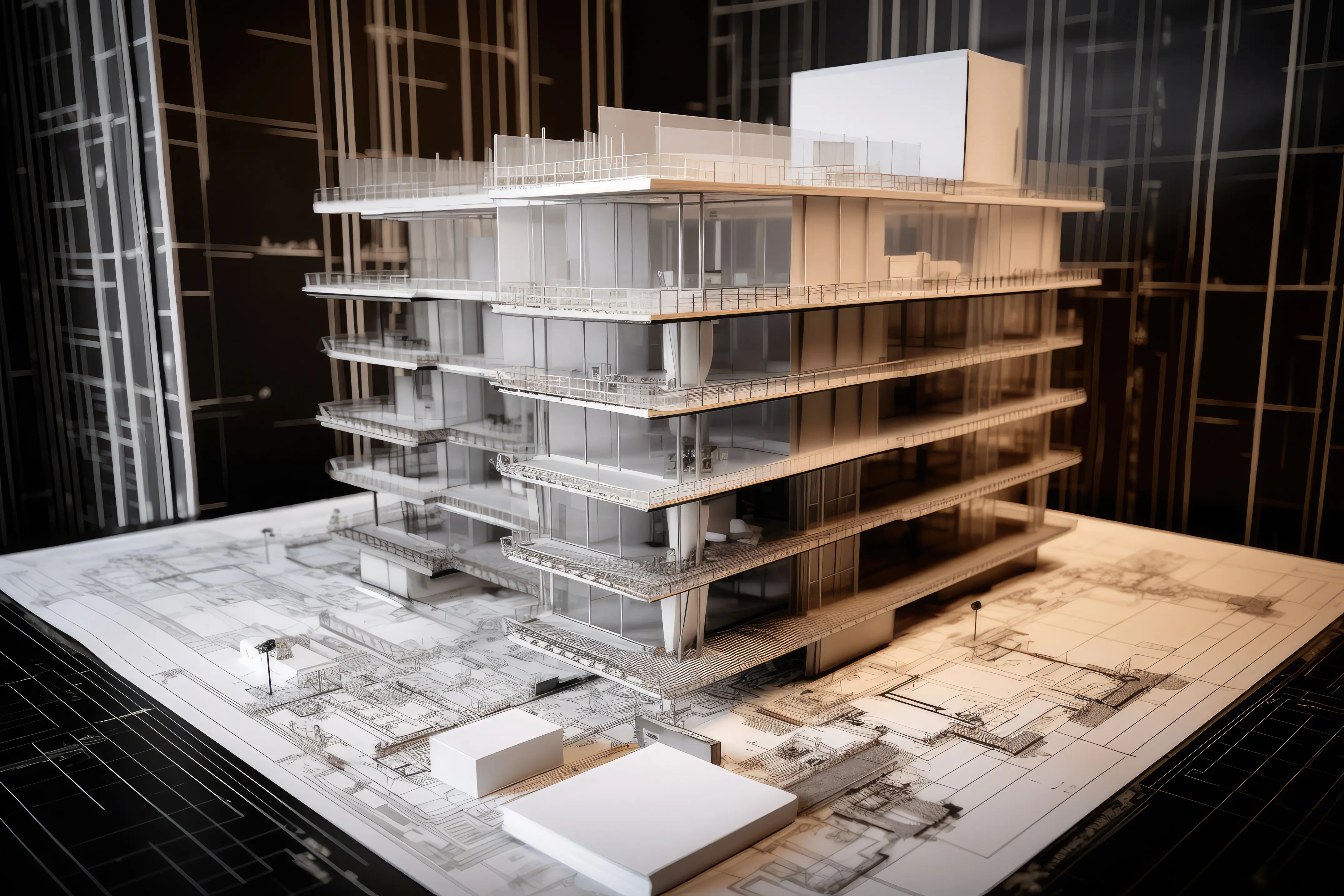

Project Management

We align stakeholders and define scope through kickoff meetings and feasibility studies, then develop integrated schedules allocating our global team across design and BIM milestones. Proactive risk workshops, automated clash detection in federated models, and rigorous QA/QC uphold quality. Transparent reporting, construction administration, and post-project reviews drive continuous improvement.

Project Kickoff & Stakeholder Alignment

Every engagement begins with a comprehensive kickoff meeting that brings together owners, architects, engineers, and contractors to define project objectives, timelines, and success criteria. We review contractual requirements, local code considerations, and sustainability targets—such as LEED or BREEAM goals—to ensure alignment from day one. This collaborative foundation fosters clear responsibilities and shared vision before design work commences.

Scope Definition & Feasibility

Building on stakeholder input, our team conducts feasibility studies and preliminary load calculations for mechanical, electrical, and plumbing systems. We assess site constraints, regulatory approvals, and budget parameters to refine the project scope. Detailed reports outline system options, energy-saving strategies, and risk factors, empowering clients to make informed decisions and set realistic deliverables.

Integrated Scheduling & Resource Planning

Using industry-standard project-management tools, we develop master schedules that synchronize design phases, BIM deliverables, and construction milestones. Resource allocation charts map our 50+ specialists across disciplines and offices in Baku, Amsterdam, Saint Petersburg, and Albuquerque, ensuring the right expertise is applied at each stage. Automated progress tracking and calendar integrations help teams stay on target and adapt to evolving requirements.

Risk & Quality Management

Proactive risk assessment workshops identify potential technical, regulatory, and logistical challenges. We implement mitigation plans—such as redundancy checks in fire-pipe hydraulics or clash-detection audits in BIM models—and conduct regular quality reviews. Our QA/QC protocols encompass peer design audits, code-compliance verifications, and site-inspection coordination to uphold ISO-aligned precision at every milestone.

BIM-Driven Coordination

Central to our project management is a federated BIM environment that integrates architectural, structural, and MEP models. Automated clash-detection routines run at predefined coordination sprints, enabling virtual issue resolution before construction starts. Shared cloud worksets and version-controlled templates ensure that all stakeholders access the latest LOD400-ready models, reducing RFIs and accelerating decision cycles.

Communication & Reporting

Transparent, timely communication underpins project success. We issue monthly progress reports, visual dashboards of key performance indicators, and budget-variance analyses, all delivered through secure on-premise portals. Weekly coordination calls and digital RFI logs keep teams informed, while tailored executive summaries ensure that leadership has clear visibility into milestones, risks, and cost implications.

Construction Administration & Support

During the construction phase, our project managers oversee submittal reviews, shop-drawing approvals, and field inspections to confirm adherence to design intent. We coordinate commissioning activities—balancing HVAC systems, validating electrical distribution, and verifying plumbing and fire-protection performance—to prepare for seamless occupancy. As-built BIM updates capture real-world conditions, providing an accurate basis for facility management.

Continuous Improvement & Lessons Learned

Post-project, we conduct comprehensive debriefs to capture successes, challenges, and process enhancements. Metrics such as clash-resolution rates, schedule adherence, and sustainability performance feed into our continuous-improvement framework. Lessons learned inform template updates, automation tool enhancements, and training curricula—ensuring each successive project benefits from the collective expertise of over 1 000 completed engagements.