How We Work

We set clear performance benchmarks through stakeholder workshops and feasibility studies. BIM-driven MEP design, paired with HVAC, electrical, and CFD analyses, optimizes efficiency and sustainability. Construction docs, COBie handovers, and 100 + C# & Dynamo tools streamline workflows. Global delivery integrates QA/QC, ASHRAE, NFPA, and green-building compliance, backed by analytics-driven continuous improvement and training.

Collaborative Planning & Feasibility

We kick off every engagement with stakeholder workshops to define objectives, site constraints, and sustainability targets. Feasibility studies combine high-level load calculations for heating, cooling, and power with spatial and regulatory analyses to establish performance benchmarks and budget parameters. This collaborative groundwork ensures that our MEP strategy and project scope align from day one.

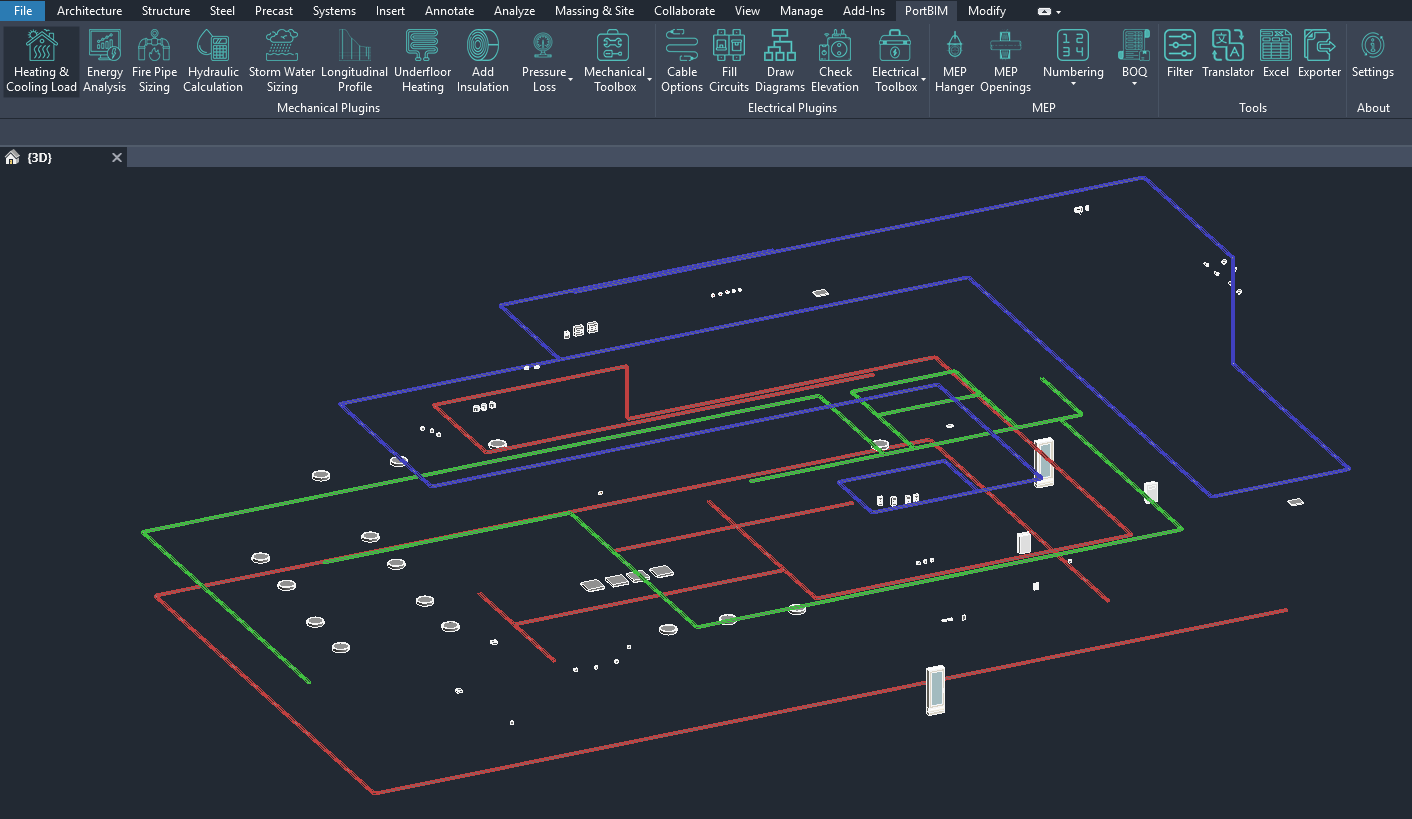

MEP Design & Engineering Analysis

Our integrated MEP design approach leverages BIM-driven workflows to coordinate mechanical, electrical, plumbing, and fire-protection systems. Advanced simulations—HVAC load studies, short-circuit and voltage-drop calculations, CFD airflow and smoke control analyses—validate system performance under real-world conditions. We embed early sustainable modeling to optimize energy and water use, earning green-building credits without compromising comfort.

BIM Integration Framework

A tailored BIM roadmap begins with workflow assessments, template deployment, and compliance checkpoints. Our centralized library of 300+ parametric families guarantees LOD400 readiness, while automated validation checks enforce model accuracy. Federated model setups and cloud-enabled reviews synchronize architectural, structural, and MEP disciplines, reducing clashes by up to 60% and delivering information-rich data for design, construction, and asset management.

Model Coordination & Documentation

Automated clash-detection routines run at every coordination sprint, enabling virtual resolution of spatial conflicts before construction. We generate construction documents directly from coordinated BIM models—embedding COBie-compliant asset registers, equipment schedules, and interactive 3D PDFs—to ensure that as-built information is accurate, accessible, and ready for facility teams from day one.

Custom Automation Tools

Our C# and Dynamo development teams deliver over 100 bespoke scripts that automate repetitive tasks—bulk parameter updates, family placement, schedule population, and clash-free model cleanup. Tools undergo rigorous QA/QC, integrate seamlessly into Revit templates, and feature intuitive Ribbon panels and WPF dialogs. Tailored training and documentation empower users to customize and extend these utilities within their on-premise environments.

Project Delivery & Administration

We develop master schedules that synchronize design phases, BIM deliverables, and construction milestones—allocating our global team across Baku, Amsterdam, Saint Petersburg, and Albuquerque. Proactive risk workshops, automated code-compliance audits, and regular progress reports ensure transparency and adaptability. During construction, we manage submittals, RFIs, site inspections, and comprehensive commissioning to confirm adherence to design intent.

Standards & Compliance

Our designs comply with ASHRAE, IEC, NFPA, and European Norms for safety and performance, while green-building targets follow LEED, BREEAM, WELL, and Estidama criteria. ISO-aligned QA/QC protocols—including peer design reviews, clash-free model audits, and code-check matrices—uphold the highest precision standards and minimize rework, ensuring every deliverable meets both statutory and client-specific requirements.

Continuous Improvement & Support

Post-project debriefs capture lessons learned—metrics on clash resolution, schedule adherence, and sustainability performance feed our continuous-improvement framework. Regular template updates, automation tool enhancements, and analytics-driven refinements keep workflows aligned with emerging technologies and evolving regulations. Ongoing training, helpdesk support, and “BIM clinics” ensure your team remains empowered and future-ready.